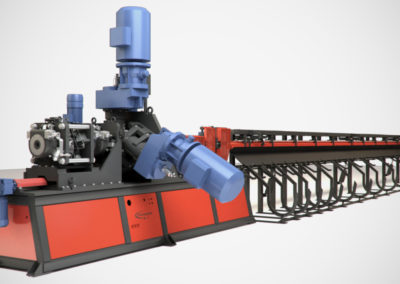

Cold Rolling And Straightening Line

Doradostar

for steel wire bars, ribbed or indented

General description

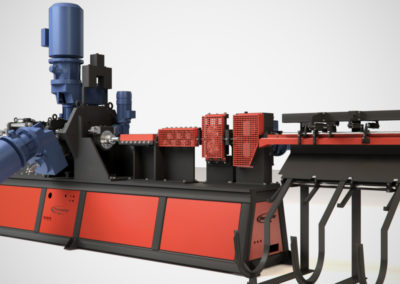

Cold Rolling And Straightening Line Doradostar is our entry level line to produce cold roll steel wire bars, ribbed or indented, to be used in products as reinforcing welded mesh, stirrups, cages and lattice girders for the civil and industrial construction, foundations and precast industry.

Cold Rolling And Straightening Line Doradostar combine the cold rolling process of the wire rod with the wire straightening and cutting of the cold rolled reinforced wire bars to the desired length.

The shape and engineering details of the line allow to produce high-quality cold roll steel bars with excellent straightness and geometrical properties of the ribbed profile. The final product can feed any type of welding reinforcing mesh machine or cut and bend equipment.

Compared to traditional straightening machines, this combined system of bar production has the advantage of achieving a high production speed with a remarkable reduction in the handling operations of the raw materials (the wire rod is processed into bundles of ribbed or indented concrete wire bars in one single line, with an obvious optimization of in-house logistics).

Cold Rolling And Straightening Line Doradostar is our entry level line to produce cold roll steel wire bars, ribbed or indented, to be used in products as reinforcing welded mesh, stirrups, cages and lattice girders for the civil and industrial construction, foundations and precast industry.

Cold Rolling And Straightening Line Doradostar combine the cold rolling process of the wire rod with the wire straightening and cutting of the cold rolled reinforced wire bars to the desired length.

The shape and engineering details of the line allow to produce high-quality cold roll steel bars with excellent straightness and geometrical properties of the ribbed profile. The final product can feed any type of welding reinforcing mesh machine or cut and bend equipment.

Compared to traditional straightening machines, this combined system of bar production has the advantage of achieving a high production speed with a remarkable reduction in the handling operations of the raw materials (the wire rod is processed into bundles of ribbed or indented concrete wire bars in one single line, with an obvious optimization of in-house logistics).

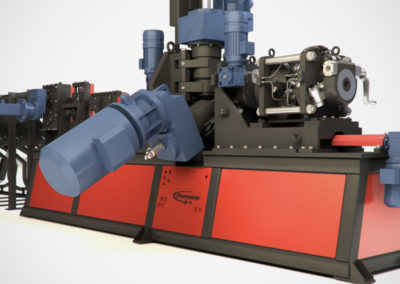

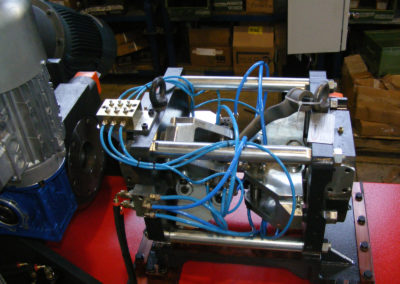

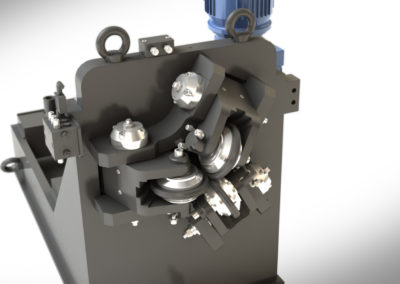

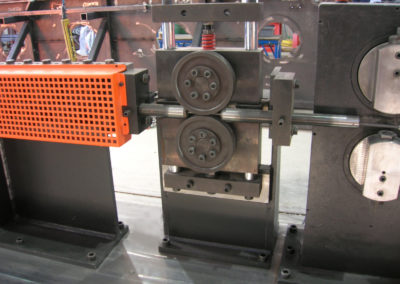

The core of the machine is the Doradostar body. Inside there are the three motorized cold rolling rolls (at the place of bullblock and wire drawing capstans) able to produce cold roll steel bars with a diameter range from Ø5 to Ø10mm and a length up to 12 meters.

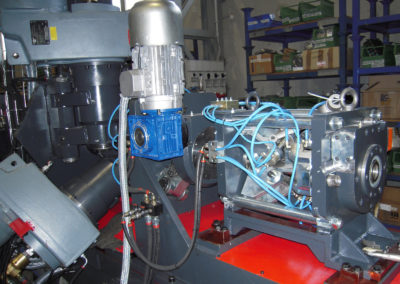

The wire rod, pulled by the three motorized cold rolling rolls driven by the PLC of the last generation, is directly cold rolled by the motorized rolls with the support of the cold rolling cassettes (equipped with idle rolls for the pre-forming operation) that reduce the diameter to the desired size improving the mechanical properties and adding the positive ribbing or the negative indentation to the wire.

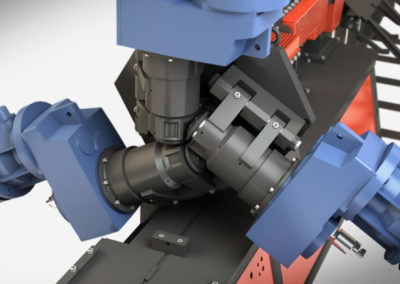

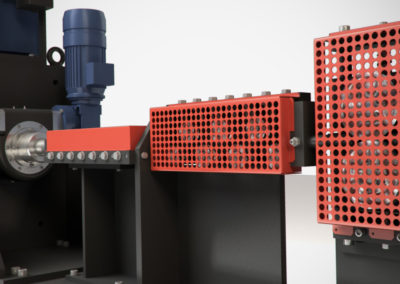

After, a system composed by high speed straightening panels fully adjustable, straighten the wire that pulled by a motorized pulling system (that creates a counter pulling downstream the capstan), permits to convey the bars towards to the continuous flying shear for the cutting of the bars to the set length.

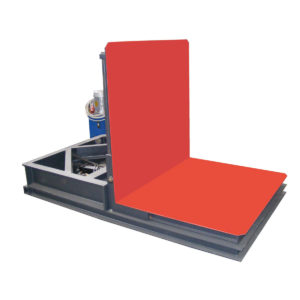

Finally, the bars are collected in the wire collector that allow the creation of partial sub-bundle and the creation of bundle of bars perfectly and automatically aligned by the machine.

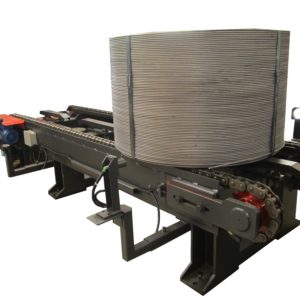

At the beginning of the machine a payoff system (with a vertical pay-off tower with two tilting fingers or with an horizontal pay-off beam, according to the wire sizes) is used to feed the machine with the plain wire produced in the hot mill process.

Other devices, like mechanical descaler or wire drawing lubricant machine are included.

Technical specifications

| Inlet Wire Diameter | 5,5 ÷ 11 m |

|---|---|

| Wire quality at entrance | low carbon wire rod |

| Outlet wire diameter | 5 ÷ 10 mm |

| Type of wire at exit | ribbed or indented cold rolled bars or coils/spools (optional) |

| Bar length | Up to 12 m |

Highlights

- Up to two straightening panels, to achieve a perfect straightness of bars at exit. The final product can feed any type of welding mesh machine or cut and

bend equipment. - High performance rotating shear unit, to allow continuous production up to 5 meters /second.

- Collecting and aligning bench for bars (adjustable up to 12 meters length or more at request).

- Descaler rolls can automatically and directly adjustable by receipt from control pulpit.

- Remote control assistance kit.

- Automatic greasing system for rolling cassettes.

- Simple maintenance procedure and fast set-up of the machine.

- Compared to traditional straightening machines, Doradostar has a higher production speed with a remarkable reduction in the handling operations.

- Smart design of the line to reduce the layout dimensions.

- Customizable according to the customer needs.