Wire Pay-Off Systems

wire pay-off systems

General description

Wire pay-off systems are devices used for the unwinding of the wire rod in the wire cold rolling, drawing and stretching machines.

Wire pay-off systems are designed to facilitates and guarantees a high-speed rod pay-off without the development of tangles/snarls and interruption.

Mainly, two different categories, can be identified:

- Vertical pay-offs

- Horizontal pay-offs

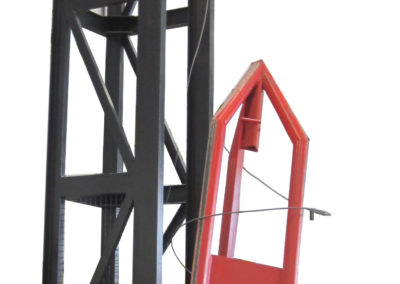

The vertical pay-offs are recommended up to medium wire rod diameters sizes and are composed of two main devices that works in combination: two (2) tilting fingers and one (1) pay-off tower.

The tilting fingers permits a continuous rod feed into the cold rolling, drawing and stretching line. They are composed of a pair of suitably shaped arms, whose structure is made of steel pipes internally filled with sand in order to reduce the noise during operations, which can turn of 90 degree on a vertical plane to reach two (2) different positions: vertical and horizontal. In the horizontal position, the fingers allow the load of the wire rod taken directly from the stock area using an overhead crane or a forklift. When the wire rod is loaded, the fingers rotates to the vertical position, ready to allow the unwinding of the wire towards the pay-off tower. Several models of tilting fingers are available in function of the dimensions and weight of the wire rods and of the height of the pay-off tower.

Wire pay-off systems are devices used for the unwinding of the wire rod in the wire cold rolling, drawing and stretching machines.

Wire pay-off systems are designed to facilitates and guarantees a high-speed rod pay-off without the development of tangles/snarls and interruption.

Mainly, two different categories, can be identified:

- Vertical pay-offs

- Horizontal pay-offs

The vertical pay-offs are recommended up to medium wire rod diameters sizes and are composed of two main devices that works in combination: two (2) tilting fingers and one (1) pay-off tower.

The tilting fingers permits a continuous rod feed into the cold rolling, drawing and stretching line. They are composed of a pair of suitably shaped arms, whose structure is made of steel pipes internally filled with sand in order to reduce the noise during operations, which can turn of 90 degree on a vertical plane to reach two (2) different positions: vertical and horizontal. In the horizontal position, the fingers allow the load of the wire rod taken directly from the stock area using an overhead crane or a forklift. When the wire rod is loaded, the fingers rotates to the vertical position, ready to allow the unwinding of the wire towards the pay-off tower. Several models of tilting fingers are available in function of the dimensions and weight of the wire rods and of the height of the pay-off tower.

The pay-off tower permits vertical unwinding high-speed without the development of tangles/snarls and interruption of the production. It is composed of a sturdy steel frame with an adequate base frame. On the top of the frame is positioned a mobile trolley, moved by an electric hoist, with a de-winding wheel. This system permits an easy wire untangling if knots occur during operations. Sides of tower are clad in thin gouge mild steel sheeting in order to contain dust, which is collected at the basis of the tower by a metal slide forward between the fingers. The stand is furnished with a safety device that automatically stops the cold rolling line in case of emergency (knot presence). A specific sensor system of new generation, which is adjustable directly by receipt from the payoff desk without the need of lower the upper basket, permit to set the sensor for the different wire diameters recording dedicated receipts. The benefits of this system can be summarized in an extreme flexibility and speed in production changes and zero downtime because the adjustments (if needed) are made in running without stopping the machine. The position of the unwinding trolley is automatically secured by a pneumatic cylinder that double-checks the correct anchoring of the hook to the structure and allow also its opening/closing. The hoist chain tension is controlled by a sensor preventing overloading of the chain. Several models of pay-off towers are available in function of the speeds of the line and the layout of the company.

The horizontal pay-offs are particularly recommended for big wire rod diameters sizes and are composed of several devices that works in combination: the horizontal pay-off beam and structure, one or two mobile trolley with retractile hook, the knot presence and the protection portals assembly.

The horizonal pay-off beam and structure is made of a sturdy steel beam with tempered steel plates (that ensures long life of the wear parts and easy maintenance) and is used for the loading and unloading of the wire rods. Sturdy support columns equipped with set of hydraulic clamps support the beam and are closed/opened during the operations (advancement of wire rod on the pay-off beam). In the uncoiling area special fins (hardened steel) and adjustable bars shake the wire reducing the knots and improving the opening of the spires.

On the upper part of the structure, a secondary beam, accommodate one (or two) motorized mobile trolley with retractile hook that drives on guides by a rack plus pinion mechanism, have the function to move, one by one, the wire rod along the main pay-off beam.

All the devices are supported by an overhead structure, fixed on the floor by 5 pairs of columns. The first two columns are moveable in multiple positions to better accommodate the butt welder. Safety is guaranteed by means of a laser scan device. The buffer of raw material ready to be processed that this solution guarantees and the high level of ergonomics for the operators in the loading/welding stations assure continuous production, maximizing the efficiency.

The knot presence of the latest generation is an innovative device that allows to drastically reduce the down time of the machine in the event of knot, avoiding the breakage of the wire rapidly stopping the line. Is made of a heavy-duty steel structure that hosts a wire conveyor basket, a series of conveyor rollers mounted on oversized bearings, two horizontal arms that can be opened manually, and a lever hinged on the horizontal axis, controlled by a pneumatic cylinder. The device detects in different way big knots or small knots stopping the line in both the case with the advantage of avoiding wire breakages. When small knots occur prevent the formation of big knots allowing the operator to solve the knot in most cases without the cutting of the wire with a quick restart of the production.

The protection portals assembly It is a series of sturdy and heavy steel welded portals, fixed directly to the floor and installed between the payoff system and the knot presence unit. Their function is to contain the material in work within a well-defined space, opening the spires during the advancement.

Wire pay-off systems are designed and manufactured by Promostar working in collaboration with our partners using the latest technologies and best brands available in the market.

Our offer is not limited to the wire pay-off systems described above, but can be completed also with a series of optional and accessories, like:

- Anti-fall friction

- Security blocks

- Pinch-roll

- Wire rod supervision kit for automatic speed line management

- Optical knot detection

- Threading motorized trolley

Technical specifications

| Working speed (max) | Up to 10 m/s |

|---|---|

| Inlet wire diameter | 5,5 ÷ 20 mm |

| Wire quality at entrance | low carbon wire rod (smooth or ribbed) |

| Weight of the wire rod | Up to 3 tons |

Highlights

- Engineered for wire cold rolling, drawing and stretching machines

- Simple maintenance procedure and fast set-up of the machine

- Suitable to install a dust conveyor integrated system

- Possibility to records and recall production receipt

- Increased safety and productivity

- Customizable according to the customer needs.