Wire equipments and accessories

General description

Wire equipments & accessories are the devices and equipments for the cold rolling, stretching and wire drawing machines.

Wire equipments & accessories are designed and manufactured by Promostar working in collaboration with our partners using the latest technologies and best brands available in the market.

The equipments & accessories available can be used for different targets and purpose, like:

- Increasing the performance of the machines (speed, productivity, etc)

- Improving the quality of the final products (according to the latest international requirements)

- Automate the processes (like automatic loading and unloading system, automatic strapping units, automatic tying machine, etc.)

- Producing new products using new technologies (stretching panels, cold rolling cassettes, die drawing boxes, ect.)

- Connectivity with the machine (IOT)

- Improving the ergonomy of the operations (reducing the efforts of the operator and increasing the efficiency)

- Increasing the level of safety (perimeter guards, laser barriers, etc).

Wire equipments & accessories are the devices and equipments for the cold rolling, stretching and wire drawing machines.

Wire equipments & accessories are designed and manufactured by Promostar working in collaboration with our partners using the latest technologies and best brands available in the market.

The equipments & accessories available can be used for different targets and purpose, like:

- Increasing the performance of the machines (speed, productivity, etc)

- Improving the quality of the final products (according to the latest international requirements)

- Automate the processes (like automatic loading and unloading system, automatic strapping units, automatic tying machine, etc.)

- Producing new products using new technologies (stretching panels, cold rolling cassettes, die drawing boxes, ect.)

- Connectivity with the machine (IOT)

- Improving the ergonomy of the operations (reducing the efforts of the operator and increasing the efficiency)

- Increasing the level of safety (perimeter guards, laser barriers, etc).

Our wire equipments & accessories are the followings:

- COLD ROLLING CASSETTES

- MAINTENANCE BENCH FOR COLD ROLLING CASSETTES

- UNSCREWING LOCKNUT DEVICE

- ROLL & ROLL-HOLDERS

- STRETCHING KIT

- DIE DRAWING BOXES

- COLLAPSIBLE SPOOLS – TAKE APART REELS

- FIXED SPOOLS – REELS

- SPIDER REELS

- OVERTURNING SPOOL DEVICE

- MANUAL STRAPPING STATION FOR COILS

- AUTOMATIC STRAPPING, LABELLING AND WEIGHING SYSTEM FOR COILS

- SCALE AND DUST COLLECTION SYSTEMS

- CHAIN AND ROLL CONVEYORS

- PULLING BULL BLOCKS

- CLEANING WIRE SYSTEMS

- WIRE PAY OFF

- DESCALER

- WIRE DRAWING LUBRICANT MACHINE

- PORTABLE WELDER EQUIPMENT

- POINTING MACHINE

- PRESSURE DIES

- ELECTRICAL – MECHANICAL REVAMPING AND REFURBISHMENT

- COLD ROLLING CASSETTES

- MAINTENANCE BENCH FOR COLD ROLLING CASSETTES

- UNSCREWING LOCKNUT DEVICE

- ROLL & ROLL-HOLDERS

- STRETCHING KIT

- DIE DRAWING BOXES

- COLLAPSIBLE SPOOLS – TAKE APART REELS

- FIXED SPOOLS – REELS

- SPIDER REELS

- OVERTURNING SPOOL DEVICE

- MANUAL STRAPPING STATION FOR COILS

- AUTOMATIC STRAPPING, LABELLING AND WEIGHING SYSTEM FOR COILS

- SCALE AND DUST COLLECTION SYSTEMS

- CHAIN AND ROLL CONVEYORS

- PULLING BULL BLOCKS

- CLEANING WIRE SYSTEMS

- WIRE PAY OFF

- DESCALER

- WIRE DRAWING LUBRICANT MACHINE

- PORTABLE WELDER EQUIPMENT

- POINTING MACHINE

- PRESSURE DIES

- ELECTRICAL – MECHANICAL REVAMPING AND REFURBISHMENT

The cold rolling cassettes are the devices used for the cold rolling of the wire. According to the type of the rolls mounted, they can produce smooth, ribbed or indented wire. Promostar offer different size of cold rollingcassettes according to the wire diameter dimensions to produce.

The maintenance bench for cold rolling cassettes is suitable for Promostar Rolling Cassettes, for cassette assembling/disassembling, rolls changing and set up, using the included optical levelling device.

The unscrewing locknut device is used during the rolls change operations to allows to easily unscrew the ring nuts of the roll holders via a hydraulic device.

The roll & roll-holders (tungsten carbide ) can be supplied acccording to the costumer’s requirements. The streching kit allow to produce wire trough the cold stretching process using two stretching panels oriented 90 degrees one to each other that are equipped with tungsten carbide rolls whose position is adjustable in function of the degree of stretching required to obtain the desired mechanical properties of the exit wire. The kit includes also the special V-shaped stretching capstans and other accessories. This kit is mounted at the place of the cold rolling cassettes and allow to transform the entry wire (rebar in coil) increasing its mechanical properties according to the market requirements.

The die drawing boxes are the devices used for the cold drawing of the wire for the production of smooth wire using pressure die. Promostar offer different solution of die drawing boxes according to the customer needs: fixed, rotating and motorized.

The collapsible spools – take apart reels allow the production of strapped coils intended for internal use (mesh machines, straightening machines, cut bends, etc.) or for external sales. They are used on horizontal or vertical spooler. We can propose different models which differ from the fact that de opening/closing is manually or automatic and that can have different weight capacity adjustable from 3 tons up to 8 tons.

The fixed spools – reels allow the production of fixed coils normally intended for internal use (mesh machines, straightening machines, cut bends, etc.). They are used on horizontal or vertical spooler. We can propose different models that can have different weight capacity adjustable from 3 tons up to 8 tons.

The spiders are steel support for the winding of the wire where static coiler deadblock machine are used (normally in the multi-pass wire drawing machine). They can have different sizes and capacity depending from the customer needs.

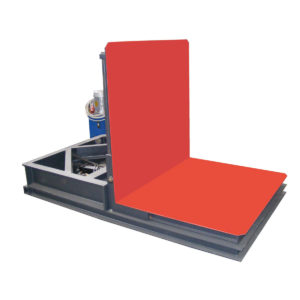

The overturning spool device thanks to a bench table rotating of 90 degrees permit to position the spools coming from the spooler, which are in horizontal position, into vertical position.

The manual strapping stations for coils permits to handle and strap the coils on the collapsible spools and/or to rotate 90 degrees the spools coming from Spooler which are in horizontal position, into vertical position.

The automatic strapping, labelling and weighing system for coils consist of an automatic strapping machine that perform the strap of coils, a printer for the stamp of the label to be placed on the strap, a system of loads cells that weighing the coils and software dedicate to manage all the operation.

The scale and dust collection systems can consist in a single belt or a system of chains belt that collect the heavy scale from the machine and transport/discharge it outside into a dedicated final container.

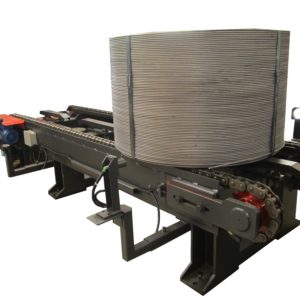

The chain and roll conveyors thanks to motorized chains or motorized rolls can transport the fixed or collapsible spools to the desired position. These conveyors consists of one or more modules (depending on the length to reach) whose motion is synchronized by a series of chains driven by a gear motor closed by protection panels.

The pulling bull blocks permits to pull the wire through the cold rolling cassettes which reduce its section in the rolling process. It can be equipped with a double deck capstan, which allows the wire to undertake two reductions with independent pulling by the lower capstan. It can be supplied with vertical or horizontal axe.

The cleaning wire systems consist in devices for the cleaning of the surface of the wire from scale and oxide before the cold rolling or wire drawing operation improving in this way the downstream process and quality of the final product. Can be simple brushes, statics and /or rotating press with iron sponge, motorized rotating brushes and/or belt grinders.

The wire pay off are parts of the machine that include all the equipment to manage the unwinding of the wire rod and the feeding of the machine. We have two different models: vertical and horizontal pay off that basically depends on the wire diameter to process.

The descaler cleans the rod surface by eliminating the scale that is the surface oxide coating by means of alternate bending of the wire rod during its passage through different descaling rolls made in hardened steel.

The wire drawing lubricant machine lubricate the rod with calcium-sodium stearate powder. The lubrication is performed by contact between the soap and the rod.

The portable welder equipment are mobile butt welder used to joint by resistance welding process the ends of wires. They are complete with wheels trolley and a grinder to eliminate the seam consequent to the welding.

The electrical – mechanical revamping and refurbishment is a service made by Promostar at different levels (mechanical, electrical, etc.). Depending on the customer needs and targets, this service foresees but is not limited to the supply of spare parts, replacement of parts of the machine or of the line with new devices and supply of new electrical cabinets (drive, plc, etc.).

For further information on these wire equipments & accessories please click on the link above.