horizontal spooler machines

Horizontal Spooler Machines

horizontal spooler machines

General description

Horizontal spooler machine is used to produce steel wire compact coils of smooth, ribbed or indented wire, to be used in products as reinforcing welded mesh, stirrups, cages and lattice girders for the civil and industrial construction, foundations and precast industry.

Horizontal spooler machine is our basic solution for the cold rolling and the stretching machines that can works with fixed or collapsible spools of different dimensions and weight capacity.

In this spooler the axis of the spool is oriented horizontally and all the operations (except for the winding) are done manually by the operator (load and unload of the spool, wire cutting and wire insertion).

The final product can feed any type of welding reinforcing mesh machine or cut and bend equipment.

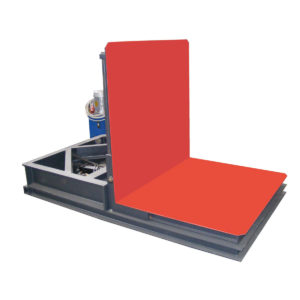

The machine has an ergonomic and compact lay-out with all main components fitted inside the compact body. This characteristic allows a remarkable reduction of noise and dust dispersion in the environment and increase the level of safety improving the working conditions for the operators.

Horizontal spooler machine is used to produce steel wire compact coils of smooth, ribbed or indented wire, to be used in products as reinforcing welded mesh, stirrups, cages and lattice girders for the civil and industrial construction, foundations and precast industry.

Horizontal spooler machine is our basic solution for the cold rolling and the stretching machines that can works with fixed or collapsible spools of different dimensions and weight capacity.

In this spooler the axis of the spool is oriented horizontally and all the operations (except for the winding) are done manually by the operator (load and unload of the spool, wire cutting and wire insertion).

The final product can feed any type of welding reinforcing mesh machine or cut and bend equipment.

The machine has an ergonomic and compact lay-out with all main components fitted inside the compact body. This characteristic allows a remarkable reduction of noise and dust dispersion in the environment and increase the level of safety improving the working conditions for the operators.

Another advantage for the operators is the rapidity of spool change or maintenance procedures because all the main components such as electric, hydraulic and other systems are conveniently arranged inside the same body in order to simplify any operation on the machine.

The spooler is formed of a sturdy steel structure designed and manufactured to support the large dynamic loadings developed during the winding of the spools. One shoulder supports the fixed center pin and the power transmission elements. The transmission elements include a pulley with relative belts for connection with the A.C. motor and a double hydraulic disk brake for the normal/emergency stoppages.

The mobile center pin, operated by hydraulic cylinder, is positioned on the opposite shoulder and, together with the fixed center pin, held in position the spool.

The wire guide device is run by an electric motor and permits the regulation of the wire spiral spacing.

The mobile center pin is hydraulically operated while a mobile platform, facilitates all the spool movements within the spooler.

The shape and engineering details of our lines allow to produce high-quality coils packaged in fixed or take a part spools with adjustable weight up to 3 tons. Normally, the coils produced are used for reinforcing mesh, stirrups, cages and lattice girders for the civil and industrial construction, foundations and precast industry.

Our wire spooler machine is normally parts of our cold rolling, stretching and wire drawing lines but can be also integrated in any kind of existing lines.

Technical specifications

| Working speed (max) | Up to 18 m/s |

|---|---|

| Wire diameter | 4 ÷ 12 (16) mm |

| Wire quality | low carbon wire rod |

| Type of wire at exit | Smooth, ribbed or indented wire coils |

| Spools dimensions | External diameter: 1250 mm |

Highlights

- Totally covered and closed by protections, with all components inside (more safety, less noise and dust pollution).

- Motorized wire guide that permits the regulation of the wire spiral pitch automatically and directly by receipt from the control pulpit.

- Suitable to works with fixed spools or collapsible spools of different dimensions and weight capacity

- Engineered for cold rolling wire smooth, ribbed, indented and/or for stretching material

- Remote control assistance kit.

- Simple maintenance procedure and fast set-up of the machine.

- Smart design of the machine in terms of layout dimensions.

- Customizable according to the customer needs.