Wire Bending Machine

Wire Zig Zag Machine

zig zag wire bending machine

General description

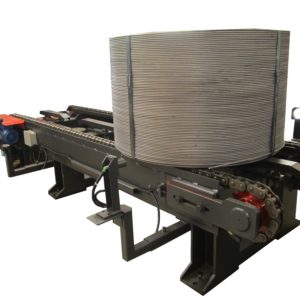

Zig Zag Wire Bending Machine is our solution to produce shaped bended pieces (“Zig Zag” shape profile) to be used as connecting elements of the reticular lattice girder (also known as PREM or REP beam).

Zig Zag Wire Bending Machine combines the bending and shaping process with the cutting to the length (head and tail) of the obtained elements. The final product can be obtained starting from coils or from bars of smooth or ribbed wire.

The shape and engineering details of the line allow to produce high-quality zig zag connecting elements according to the geometrical shape and dimensions requested by the customers. The final products can assume different shapes in terms of pitch and height of the zig zag bending. Furthermore, the wide possible diameter range and the programmable length of the entry wire used allow to customize according to your needs the final element. The final product does not require further processing and is ready to be used on site.

Compared to manual manufacturing methods, the advantages of this kind of automatic welding wire machine is the productivity, greater flexibility and rapidity in production changes of the diameter sizes, the quality and the repeatability of the product, the limited number of operators (usually only one operator controls the whole plant) and the production and maintenance costs.

The Wire Zig Zag machine is composed of different parts.

Zig Zag Wire Bending Machine is our solution to produce shaped bended pieces (“Zig Zag” shape profile) to be used as connecting elements of the reticular lattice girder (also known as PREM or REP beam).

Zig Zag Wire Bending Machine combines the bending and shaping process with the cutting to the length (head and tail) of the obtained elements. The final product can be obtained starting from coils or from bars of smooth or ribbed wire.

The shape and engineering details of the line allow to produce high-quality zig zag connecting elements according to the geometrical shape and dimensions requested by the customers. The final products can assume different shapes in terms of pitch and height of the zig zag bending. Furthermore, the wide possible diameter range and the programmable length of the entry wire used allow to customize according to your needs the final element. The final product does not require further processing and is ready to be used on site.

Compared to manual manufacturing methods, the advantages of this kind of automatic welding wire machine is the productivity, greater flexibility and rapidity in production changes of the diameter sizes, the quality and the repeatability of the product, the limited number of operators (usually only one operator controls the whole plant) and the production and maintenance costs.

The Wire Zig Zag machine is composed of different parts.

The first part of the machine is the feeding system. Thanks to rolls conveyors (idle or motorized on request) the entry material (smooth or ribbed wire bars) move towards the motorized pinch-roll unit. Other type of feeding systems are available on request like the automatic feeding system with bars storage or the unwinding feeding system when the raw material is packaged in coils at the place of bars.

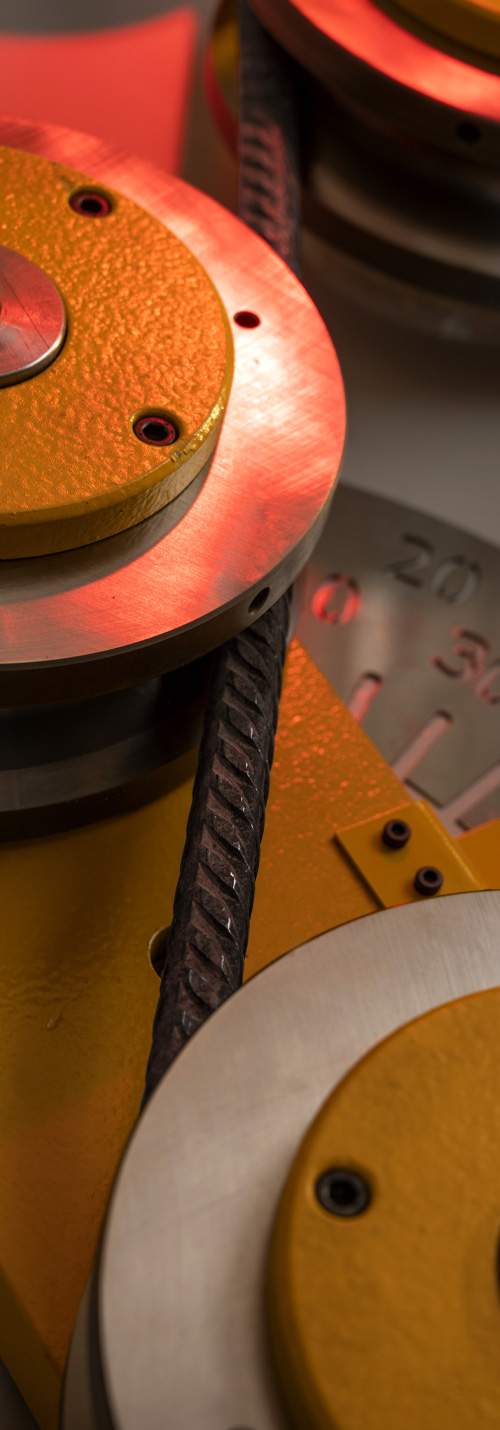

The central part of the machine, the core of the line, is the shaping unit. It consists on three motorized trolley that bring the shaping mandrels. The stroke of the trolleys is fully programmable in function of the pitch and the height of the zig zag elements to obtain. At the exit, a cutting unit, permits the cut of the head and the tail of the final product.

The last part of the machine is the collecting bench that permits to receive the zig zag elements and to discharge it to the storage unit (manual or automatic with multi positions storage on request).

This kind of machine is part of our division of special machine and obviously it can be customized upon the request of our customers based on the different shapes and dimensions of the final products (the design starts from the final product to be produced).

In the higher level of customization, the lines can be equipped with an automatic loading system composed by a multi position storage for bars and an automatic arm that load the bar from the selected position of the storage directly to the machine. At the exit is it possible to integrate the downloading system of the pieces with an automatic multi position storage that receive the products dividing them by type.

Due to the special final products to realize, all the technical information reported are to be considered as indicative and we suggest to contact us for further details.

Technical specifications

| Pitch of the bending | 150 ÷ 850mm (variable) |

|---|---|

| Height of the product | 120 ÷ 850mm (variable) |

| Internal radius | 2,5x wire diameter |

| Tolerance on the pitch | +/- 10 mm |

| Tolerance on the height | +/- 5 mm |

| Planarity of the product | +/- 5 mm |

| Wire quality at entrance | low carbon wire rod |

| Productivity | 150 seconds (referred to a bar with a diameter of 20 mm and a total length of 12 meters, shaped at medium dimensions of pitch and height |

Highlights

- Remote control assistance kit.

- Shape and dimensions of the final product fully programmable and customizable.

- Possibility to integrate (optional) an automatic loading system.

- Available (optional) of an automatic multi position storage for collect the final products

- Simple maintenance procedure and fast set-up of the machine.

- Smart design of the line in terms of layout dimensions.

- Customizable according to the customer needs.