cold drawn

steel wires

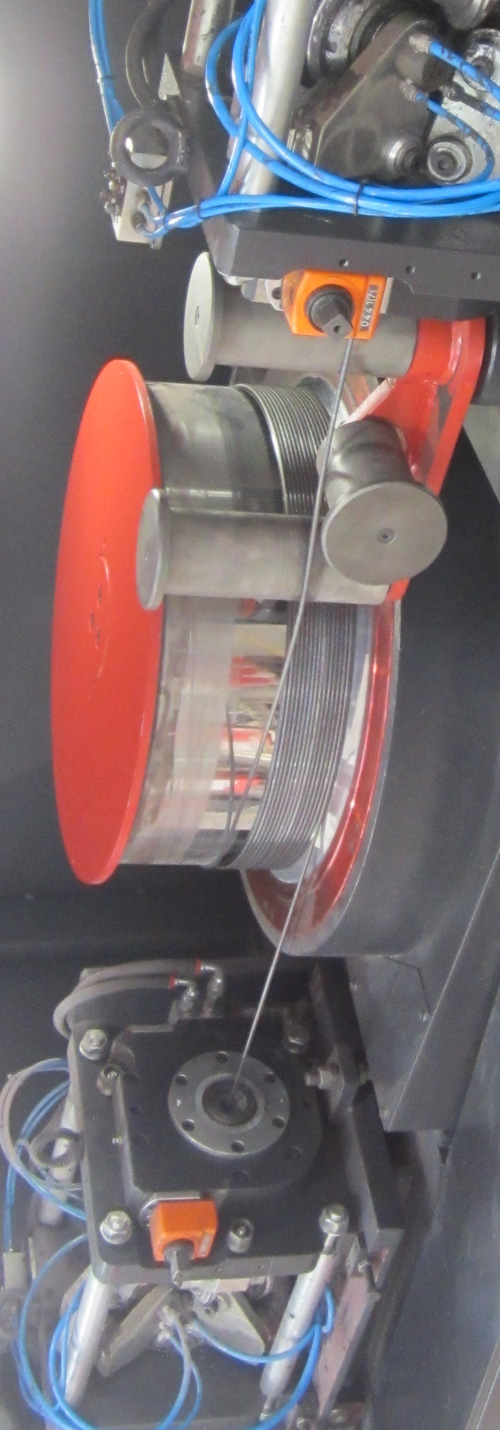

Machines and wire equipments

General description

Cold drawn steel wire coil is a product obtained starting from the wire rod that is transformed with the process of drawing (through drawing boxes equipped with drawing dies) made without heat supply and winded and packaged on spiders, fixed or collapsible spools.

Cold drawn steel wire coil, thanks to the drawing process that reduces the diameter of the plain wire to the desired size it is a product with an excellent roundness with increased mechanical properties compared to the entry wire rods.

The final product applications are normally for the industrial or agricultural sector for the production of smooth wire, galvanized wire, bright wire, barbed wire, bailing wire, barrier strand, fencings wire, spring wire, nails and tying wire.

Thanks to more than 40 years of experience in the field of process of rolling, we manufacture high performances automatic turn key plants, that are tailor made on the needs of our customers in terms of layout, products sizes, mechanical properties, level of automation and which allow to finally reduce the transformation costs for each tons of steel wire produced.

Cold drawn steel wire coil is a product obtained starting from the wire rod that is transformed with the process of drawing (through drawing boxes equipped with drawing dies) made without heat supply and winded and packaged on spiders, fixed or collapsible spools.

Cold drawn steel wire coil, thanks to the drawing process that reduces the diameter of the plain wire to the desired size it is a product with an excellent roundness with increased mechanical properties compared to the entry wire rods.

The final product applications are normally for the industrial or agricultural sector for the production of smooth wire, galvanized wire, bright wire, barbed wire, bailing wire, barrier strand, fencings wire, spring wire, nails and tying wire.

Thanks to more than 40 years of experience in the field of process of rolling, we manufacture high performances automatic turn key plants, that are tailor made on the needs of our customers in terms of layout, products sizes, mechanical properties, level of automation and which allow to finally reduce the transformation costs for each tons of steel wire produced.

Our offer is not limited to the construction of machines and equipment. If required, we are also able to supply valid training, technical assistance and consulting to improve the production of the drawing process; These services are the keys to reach the target and maintain it over time in terms of efficiency and performance of the plant as well as in terms of correct mechanical properties of the wire produced.

Technical specifications

| Working Speed (max) | Up to 30 m/s for coils/spools |

|---|---|

| Inlet Wire Diameter | 5,5 ÷ 10 mm |

| Wire quality at entrance | low carbon wire rod |

| Outlet wire diameter | 1 ÷ 8 mm |

| Type of wire at exit | Smooth wire coils |

| Coil weight (max) | Up to 3 tons |

Our cold drawing lines for coils are the followings

COLD WIRE DRAWING LINE MAIASTAR DV

COLD WIRE DRAWING LINE MAIASTAR DO

Both are multi-pass drawing machines that can do more than one reduction on the wire where the total number of the drafts (or reduction) depend on the final wire diameter to produce. The main difference between the two lines is the orientation of the axes on the capstans. In the model MAIASTAR DV they are oriented vertically while in the model MAIASTAR DO they are oriented horizontally.

The high customization and the number and type of devices that can be installed makes the machines very flexible.

Depending on the packaging of the final product, at the exit, the machines can be equipped with static coiler deadblock machines that collect the wire on spider reels or with horizontal wire spoolers that collect the wire on fixed or collapsible spools.

In the highest level of automation of our plants, the above mentioned lines can be also equipped with automatic vertical wire spoolers that make all the operations like insertion of the wire, cutting, change of the spools, samples taking, strapping, labeling and weighing of the coils without any intervention of the operator.

The shape and engineering details of our lines allow to produce high-quality cold drawing coils packaged in fixed or take a part spools. Normally, the coils produced are used for industrial or agricultural sector as smooth wire, galvanized wire, bright wire, barbed wire, bailing wire, barrier strand, fencings wire, spring wire, nails and tying wire.

For further information on these machines please click on the link above.