Die Drawing Boxes

die drawing boxes

General description

Die drawing boxes are used for the cold drawing process of the wire rod made without heat supply.

Die drawing boxes thanks to the drawing process that reduces the diameter of the plain wire to the desired size it is a product with an excellent roundness with increased mechanical properties compared to the entry wire rods.

The final product applications are normally for the industrial or agricultural sector for the production of smooth wire, galvanized wire, bright wire, barbed wire, bailing wire, barrier strand, fencings wire, spring wire, nails and tying wire.

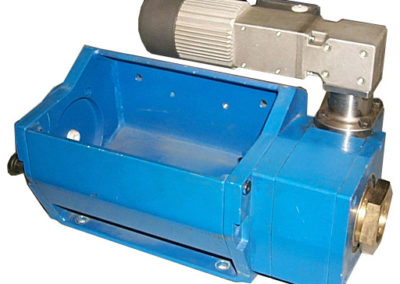

The drawing boxes consist of a sturdy welded steel frame on which are mounted the supports that allow the use of pressure die to cold drawn the wire.

Each drawing boxes is equipped with a soap container for the lubrification of the wire to reduce the friction generated between the wire and the die.

Die drawing boxes are used for the cold drawing process of the wire rod made without heat supply.

Die drawing boxes thanks to the drawing process that reduces the diameter of the plain wire to the desired size it is a product with an excellent roundness with increased mechanical properties compared to the entry wire rods.

The final product applications are normally for the industrial or agricultural sector for the production of smooth wire, galvanized wire, bright wire, barbed wire, bailing wire, barrier strand, fencings wire, spring wire, nails and tying wire.

The drawing boxes consist of a sturdy welded steel frame on which are mounted the supports that allow the use of pressure die to cold drawn the wire.

Each drawing boxes is equipped with a soap container for the lubrification of the wire to reduce the friction generated between the wire and the die.

The heat produced by the drawing process is eliminated by cooling water circuit flowing directly the drawing dies (In the rotating drawing boxes the water flow reverses alternately for increase the turbulence and the efficiency of the thermal interchange).

Each drawing die is mounted on a perfectly aligned bracket to allow easy replacement.

Die drawing boxes are designed and manufactured by Promostar working in collaboration with our partners using the latest technologies and best brands available in the market.

We can supply three (3) different types of die drawing boxes:

- Fixed

- Rotating - idle

- Rotating - motorized

In the fixed die drawing boxes the pressure die is fixed while in the rotating type rotate during the advancement of the wire reducing in this way the friction generated between the wire and the die.

In the “rotating – idle” the rotation of the die is obtained through the advancement of the wire while in the “rotating – motorized” the rotation of the die is given by a dedicated motor and therefore is independent from the wire advancement.

Our offer is not limited to the drawing boxes, but can be completed also with a series of optional and accessories, like:

Technical specifications

| Working speed (max) | Up to 30 m/s |

|---|---|

| Inlet wire diameter | 5,5 ÷ 6 mm |

| Wire quality at entrance | low carbon wire rod |

| Outlet wire diameter | 1 ÷ 4 mm |

| Type of wire at exit | Smooth, ribbed or indented wire |

| Die dimensions | Cylindrical Ø43×30 mm |

Highlights

- Engineered for cold drawing process, with fast changing and settings.

- Automatic cooling system.

- Simple maintenance procedure and fast set-up of the machine.