Rolls & roll-holders

used for the cold rolling process

General description

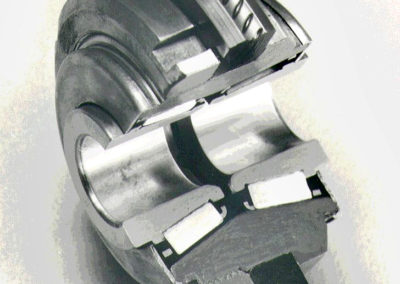

Rolls & roll-holders are used for the cold rolling process in the cold rolling cassettes.

Rolls & roll-holders are made integrally in tungsten carbide.

We have different shapes of the rolls that varies according to each stage of the process (oval, round, sizing, forming and profiling rolls) and on the final shape of the wire (smooth, ribbed or indented). Other aspect like the diameter of the inlet and outlet wire product and standard rules to comply (EN, DIN, ASTM, etc.), are taken in consideration to define the correct dimensions and geometrical shapes of the dimensions of the ribs, orientation, pitch and “fr” factor.

Rolls & roll-holders are used for the cold rolling process in the cold rolling cassettes.

Rolls & roll-holders are made integrally in tungsten carbide.

We have different shapes of the rolls that varies according to each stage of the process (oval, round, sizing, forming and profiling rolls) and on the final shape of the wire (smooth, ribbed or indented). Other aspect like the diameter of the inlet and outlet wire product and standard rules to comply (EN, DIN, ASTM, etc.), are taken in consideration to define the correct dimensions and geometrical shapes of the dimensions of the ribs, orientation, pitch and “fr” factor.

It is also possible to customize the wire produced adding the company name or logo on the surface of the profiling rolls.

Rolls & roll-holders are offered working in collaboration with our partners using the latest technologies and best brands available in the market.

Technical specifications

| Inlet wire diameter | 5,5 ÷ 20 mm |

|---|---|

| Wire quality at entrance | low carbon wire rod |

| Outlet wire diameter | 4 ÷ 19 mm |

| Type of wire at exit | Smooth, ribbed or indented wire |

| Roll holder pins | from Ø26 or Ø32mm |

| Roll dimensions | External diameter from Ø123 to Ø200 mm |

Highlights

- Engineered for cold rolling cassettes

- Customizable according to the customer demands: possibility to add your company name or logo on the profiling rolls

- Simple maintenance procedure and fast set-up