Wire Lubricant Machines

wire lubricant machines

General description

Wire Lubricant machines are used to lubricates the entry wire rod with calcium-sodium stearate powder before the wire cold rolling or drawing process.

Wire Lubricant machines performs the lubrication of the wire rod putting in direct contact the soap powder with the rod surface.

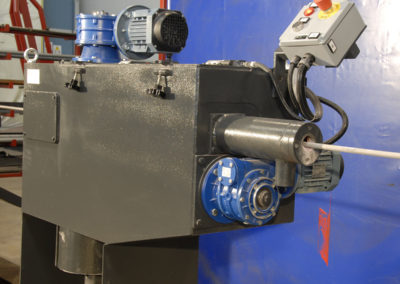

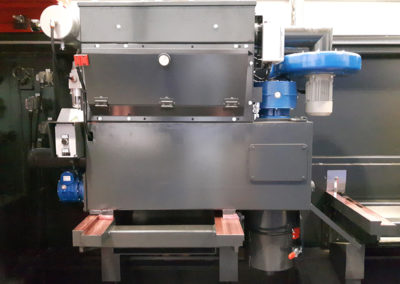

They are composed of a rigid base and support, manufactured in steel on which are installed two motorized (2) endless screws, one horizontal and one vertical whose function is to move continuously the lubricant powder to the wire rod level. A convenient upper access allows quick lubricant powder loading operations while a lower access permits the download of the exhausted soap powder.

Wire Lubricant machines are used to lubricates the entry wire rod with calcium-sodium stearate powder before the wire cold rolling or drawing process.

Wire Lubricant machines performs the lubrication of the wire rod putting in direct contact the soap powder with the rod surface.

They are composed of a rigid base and support, manufactured in steel on which are installed two motorized (2) endless screws, one horizontal and one vertical whose function is to move continuously the lubricant powder to the wire rod level. A convenient upper access allows quick lubricant powder loading operations while a lower access permits the download of the exhausted soap powder.

The device is totally closed ands suitable to be equipped with the installation of a filtering and recycling system that put the entire soap into depression limiting in this way the dispersion of soap powder inside the machine body, therefore reducing its consumption. As a result, the excess of soap powder over the wire surface is absorbed, and the filter cleaning system makes it fall again into the soap box.

Technical specifications

| Working speed (max) | Up to 10 m/s |

|---|---|

| Inlet wire diameter | 5,5 ÷ 20 mm |

| Wire quality at entrance | low carbon wire rod |

Highlights

- Totally covered and closed by protections, with all components inside (more safety, less noise and dust pollution), ideal for filtering and recycling system connecting.

- Fully integrated with the layout of our machines

- Designed for fast soap loading operation for downtime reduction

- Less downtimes for maintenance and cleaning the machines

- Improve the lubricant of the entry wire rod