welded wire machine tunnel mesh

Tunnel Mesh

for the realization of curved reinforcing armatures for concrete elements for tunnels applications

General description

Welded wire machine tunnel mesh is our solution to produce electro-welded rectilinear and curvilinear elements designed for the realization of curved reinforcing armatures for concrete elements for tunnels applications (tunnel lattice girder).

Welded wire machine tunnel mesh combines the process of electro welding (through welding heads) with the cutting to the length and the shaping of the tunnel elements.

The shape and engineering details of the line allow to produce high-quality product according to the geometrical shape and dimensions requested by the customers. The final product does not require further processing and is ready to be used in the concrete armatures for tunnel elements.

Compared to manual manufacturing methods, the advantages of this kind of automatic welding wire machine is the productivity, greater flexibility and rapidity in production changes of the diameter sizes, the quality and the repeatability of the product, the limited number of operators (usually only one operator controls the whole plant) and the production and maintenance costs.

Welded wire machine tunnel mesh is our solution to produce electro-welded rectilinear and curvilinear elements designed for the realization of curved reinforcing armatures for concrete elements for tunnels applications (tunnel lattice girder).

Welded wire machine tunnel mesh combines the process of electro welding (through welding heads) with the cutting to the length and the shaping of the tunnel elements.

The shape and engineering details of the line allow to produce high-quality product according to the geometrical shape and dimensions requested by the customers. The final product does not require further processing and is ready to be used in the concrete armatures for tunnel elements.

Compared to manual manufacturing methods, the advantages of this kind of automatic welding wire machine is the productivity, greater flexibility and rapidity in production changes of the diameter sizes, the quality and the repeatability of the product, the limited number of operators (usually only one operator controls the whole plant) and the production and maintenance costs.

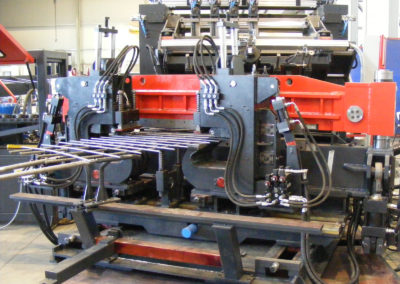

The Tunnel Mesh machine is composed of different parts.

The first part of the machine is the feeding system. Thanks to the pay-off units and the motorized pulling rolls the entry material (smooth or ribbed compact coil wire) is unwound ad pull towards the welding unit in a constant way at the right speed.

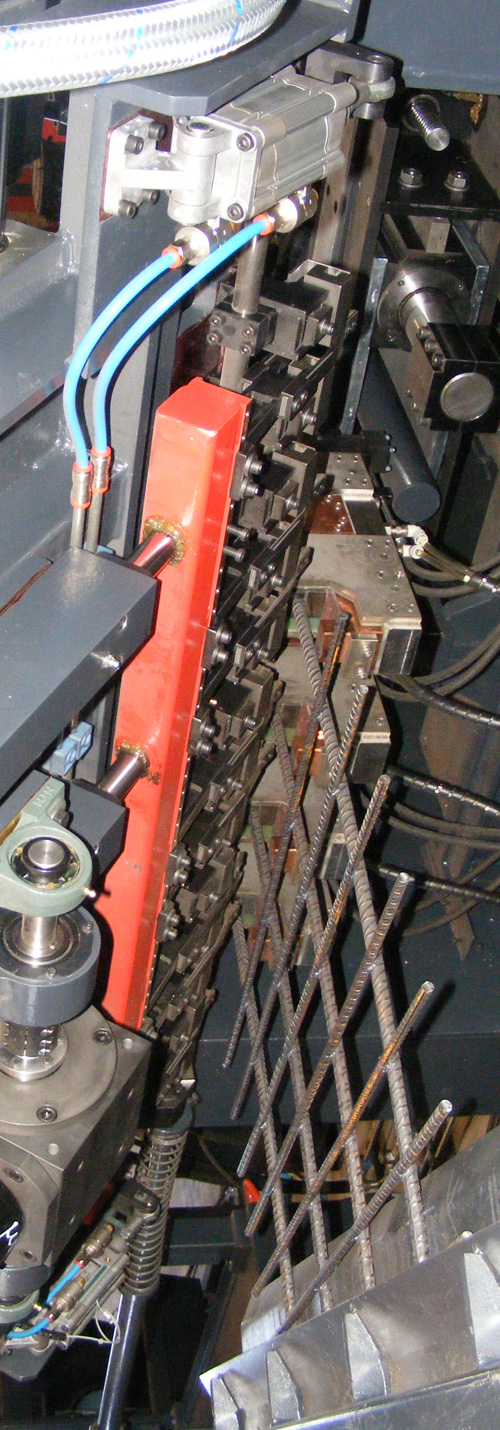

Then follow other groups, like insertion units, advancement group and straightening group that prepare and brings the longitudinal and the cross wire inside the welding unit.

Thanks to a resistance electro-welding process, the longitudinal wires are welded with the cross wires.

If required, it is possible also to bend the cross-wire ends, thanks to the action of a bending device.

When the dimension of the tunnel mesh is reached, a shear unit cut it to the desired length.

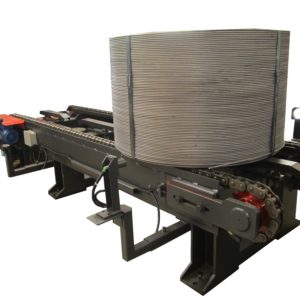

A series of movable metallic tables at the exit, are manually oriented according to the radius of curvature of the produced element, support the mesh during the exit phase and allow the operator to take the final product once it is completed.

We have different level of customization: starting from the basic solution where the machine can produce standard tunnel elements with two longitudinal wire up to the high level solution where the machine can produce tunnel elements with four longitudinal and with the possibility to bend the cross wire ends. Furthermore, the machine can be also equipped with an automatic manipulator (robot) for evacuation and stacking of the welded elements.

This kind of machine is part of our division of special machine and obviously it can be customized upon the request of our customers based on the different shapes and dimensions of the final products (the design starts from the final product to be produced).

Due to the special final products to realize, all the technical information reported are to be considered as indicative and we suggest to contact us for further details.

Technical specifications

| Longitudinal wire number | min. 2 – max. 4 |

|---|---|

| Longitudinal wire diameter | from 8 mm to 16 mm |

| Cross wire number | 1 |

| Cross wire diameter | from 8 mm to 12 (16) mm |

| Wire quality | smooth or ribbed low carbon wire |

| Curved mesh lenght | from 1500 to 6000 mm |

| Curved mesh width | from 150 to 1000 mm |

| Cross wire maximum length (without bending) | 1300 mm |

| Longitudinal wires minimum distance | min 70 mm – max. 300 mm |

| Minimum bending radius | 2000 mm |

| Welding speed | from 15 cycles/min up to maximum 40 cycles/min |

Highlights

- Possibility to produce tunnel elements with two or four longitudinal wires.

- Engineered to produce also rectilinear mesh.

- Automatic bending unit (optional) allow to bend the cross wires ends.

- Automatic robot manipulator (optional) for the evacuation and stacking of

the welded elements - Remote control assistance kit.

- Simple maintenance procedure and fast set-up of the machine.

- Smart design of the line in terms of layout dimensions.

- Customizable according to the customer needs.