Cold stretching and respooling lines

Machines and wire equipments

General description

Cold stretching and respooling lines are used to produce cold stretched steel wire in coils and bars.

Cold stretching and respooling lines manufactured by Promostar are complete lines or just single unit able to transform the rebar in coil with the process of stretching (through stretching panels equipped with rolls) in order to increase the mechanical properties of the wire according to the market requirements in terms of tensile strength, yield strength and final elongation (normally called Agt) practically without changing the entry wire diameter.

The final product applications are normally reinforcing mesh, stirrups, cages and lattice girders for the civil and industrial construction, foundations and precast industry.

Compared to a hot rolling plant, the advantages of a stretching rolling plant are the much lower investment costs, the cheaper cost of the steel heat (no need to add expensive alloy elements), the space required for the installation, greater flexibility and rapidity production changes of the diameter sizes, the quality of packaging of the final product, the limited number of operators (usually only one operator controls the whole plant) and the production and maintenance costs.

Due to the continuous improvement made by our internal research and development department, we are able to supply complete machines or just single unit that, depending on the quality of the entry rebar in coil material, can produce exit wire material compliant to the local countries norms for the concrete applications like for example (but not only): ASTM A82, ASTM A706, ASTM A1064, DIN 488, SFS1300, IRAM/IAS U500, NCH1173, NBR7480, NCT2289, AS/NZS4671, NTP339 for the production of material according to the grade B500B, B500C, grade 60, grade 80, CA-50 and CA-60.

Cold stretching and respooling lines are used to produce cold stretched steel wire in coils and bars.

Cold stretching and respooling lines manufactured by Promostar are complete lines or just single unit able to transform the rebar in coil with the process of stretching (through stretching panels equipped with rolls) in order to increase the mechanical properties of the wire according to the market requirements in terms of tensile strength, yield strength and final elongation (normally called Agt) practically without changing the entry wire diameter.

The final product applications are normally reinforcing mesh, stirrups, cages and lattice girders for the civil and industrial construction, foundations and precast industry.

Compared to a hot rolling plant, the advantages of a stretching rolling plant are the much lower investment costs, the cheaper cost of the steel heat (no need to add expensive alloy elements), the space required for the installation, greater flexibility and rapidity production changes of the diameter sizes, the quality of packaging of the final product, the limited number of operators (usually only one operator controls the whole plant) and the production and maintenance costs.

Due to the continuous improvement made by our internal research and development department, we are able to supply complete machines or just single unit that, depending on the quality of the entry rebar in coil material, can produce exit wire material compliant to the local countries norms for the concrete applications like for example (but not only): ASTM A82, ASTM A706, ASTM A1064, DIN 488, SFS1300, IRAM/IAS U500, NCH1173, NBR7480, NCT2289, AS/NZS4671, NTP339 for the production of material according to the grade B500B, B500C, grade 60, grade 80, CA-50 and CA-60.

Thanks to more than 40 years of experience in the field of process of rolling, we manufacture high performances automatic turn key plants, that are tailor made on the needs of our customers in terms of layout, products sizes, mechanical properties, level of automation and which allow to finally reduce the transformation costs for each tons of steel wire produced.

Our offer is not limited to the construction of machines and equipment. If required, we are also able to supply valid training, technical assistance and consulting to improve the production of the stretching process; These services are the keys to reach the target and maintain it over time in terms of efficiency and performance of the plant as well as in terms of correct mechanical properties of the wire produced.

Technical specifications

| Working Speed (Max) | Up to 14 m/s for coils/spools Up to 8 m/s for bars |

|---|---|

| Inlet Wire Diameter | 6 ÷ 20 Mm |

| Wire quality at entrance | low carbon rebar in coil |

| Outlet wire diameter | 6 ÷ 20mm |

| Type of wire at exit | ribbed wire compact coils or bars |

| Coil weight (max) | Up to 8 tons |

| Bar length | Up to 12 m |

Final products

Our cold stretching and respooling lines

Our cold stretching and respooling lines are divided in two categories depending on the kind of final product:

COLD STRETCHED STEEL WIRE COILS

COLD STRETCHED STEEL WIRE BARS

The lines for COLD STRETCHED STEEL WIRE COILS is the following:

COLD STRETCHING AND RESPOOLING LINE ARGOSTAR

The Argostar combines the stretching process of the rebar in coil with the spooling of the stretched reinforced steel wire to the desired coil weight by mean of the Automatic vertical spooler. It is also used for respooling purpose in those case where there is no need to increase the mechanical properties of the material but only to obtain very compact coils.

The core of the line is the double bullblock and the Argostar body.

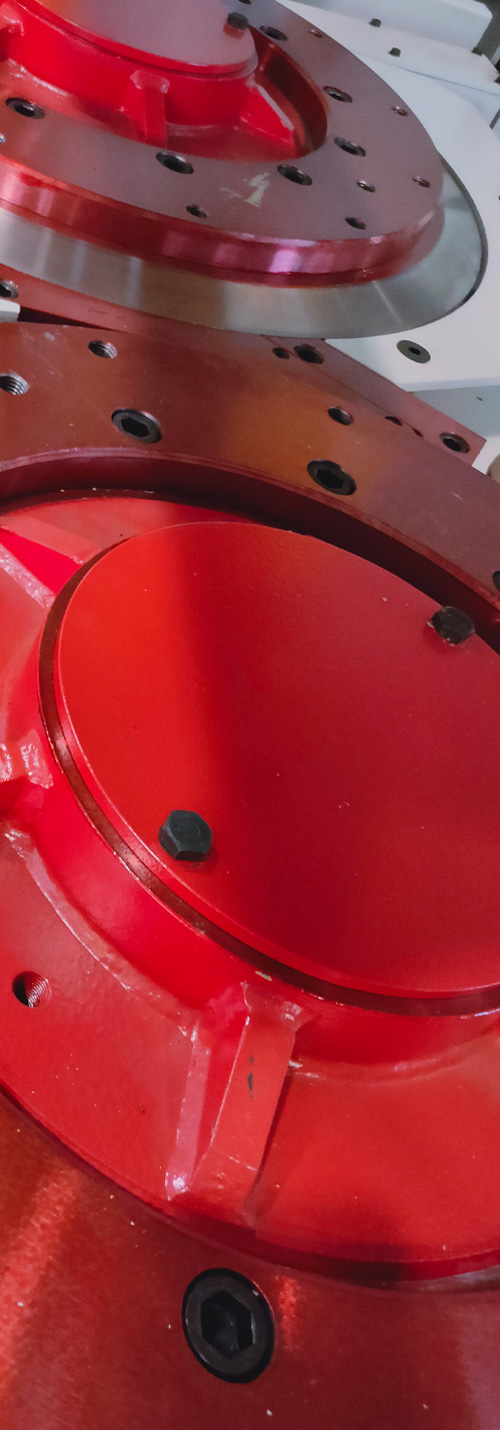

The double bullblock is composed by two vertical axes bullblocks that thanks to their position, force the wire to make an “S” path, with the advantage to give an additional degree of stretching to the material. The wire drawing capstans are V shape type (with the possibility also to install smooth capstans for cold rolling production) and permit to produce cold stretched steel wire coils with a diameter range from Ø6 to Ø20mm and a weight capacity up to 8 tons.

The wire rod, pulled by the high-performances bullblock and driven by the PLC of the last generation, is cold stretched by the two stretching panels placed inside the Argostar boby, that are oriented 90 degrees one to each other (to guarantee an uniform elongation on all the surface of the wire) and that (depending on the degree of stretching set up on the control panel) improve the final mechanical properties the wire.

For further information on these machines please click on the link above.

The machine for COLD STRETCHED STEEL WIRE BARS is the following:

COLD STRETCHING AND STRAIGHTENING MACHINE TYPE GEMINISTAR

Cold stretching and straightening machine type Geministar combines the cold stretching process of the wire rod with the wire straightening and cutting of the cold stretched reinforced wire bars to the desired length.

Compared to traditional straightening machines, this combined system of bar production has the advantage of achieving a high production speed with a remarkable reduction in the handling operations of the raw materials (the rebar in coil is processed into bundles of ribbed concrete wire bars in one single line, with an obvious optimization of in-house logistics).

The core of the machine is the Geministar body. Inside there is the bullblock with horizontal axis equipped with the wire drawing capstans able to produce cold stretched steel bars with a diameter range from Ø6 to Ø18mm and a length up to 12 meters.

The wire rod, pulled by the high-performances bullblock and driven by the PLC of the last generation, is cold stretched by the two stretching panels that are oriented 90 degrees one to each other (to guarantee an uniform elongation on all the surface of the wire) and that (depending on the degree of stretching set up on the control panel) improve the final mechanical properties the wire.

For further information on these machines please click on the link above.